Electric Induction Furnace Suppliers

Hani Metallurgy is one of the high-quality electric induction furnace suppliers and manufacturers. High-efficiency induction furnace & to melt various metals and save energy.

Induction Melting Furnace Power Calculation

The formula for calculating the induction melting furnace power calculation is: P=(C×T×G) ÷ (0.24×S×η) C=Specific heat of material (kcal/kg℃)

Electric Induction Furnace Manufacturer

Hani Metallurgy is a professional electric induction furnace manufacturer. The company specializes in producing many high-efficiency induction furnaces, such as intermediate frequency coreless induction furnaces, core copper melting furnaces, induction diathermy furnaces, power frequency core insulation (iron) furnaces, etc.

Arc Furnace and Induction Furnace

Compared with ordinary electric arc furnace, induction furnace has the following characteristics in terms of refining capacity & adaptability.

What is Induction Furnace?

Induction furnace is an induction heating equipment that everyone is familiar with. It is mainly composed of two parts and some auxiliary…..

Induction Furnace Power Supply

The induction furnace power supply and capacitor box are the most basic components in the intermediate frequency heating furnace……

Induction Melting Furnace for Sale

The induction melting furnace for sale is currently a commonly used metal non-standard induction heating equipment. it is necessary to…

Induction Furnace For Steelmaking

In order to improve the production capacity of induction furnace for steelmaking, Hani Metallurgy makes reasonable designs in terms of hardware…..

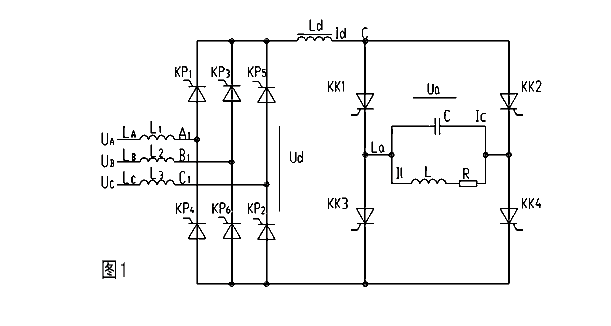

Induction Furnace Circuit and Principle

In the induction furnace, the induction furnace circuit is very similar to a transformer. The induction electrothermal effect is used to complete the metal smelting process. The power supply is generally divided into three types: high frequency (above 10 kHz), intermediate frequency (50 Hz ~ 10 kHz), and power frequency (50 or 60 Hz).

New Trends in Submerged Arc Furnace Technology

This article will give introduce the solution of the online monitoring system for new trends in submerged arc furnace technology in today’s main application fields: ferroalloys, non-ferrous, special application, and recycling.