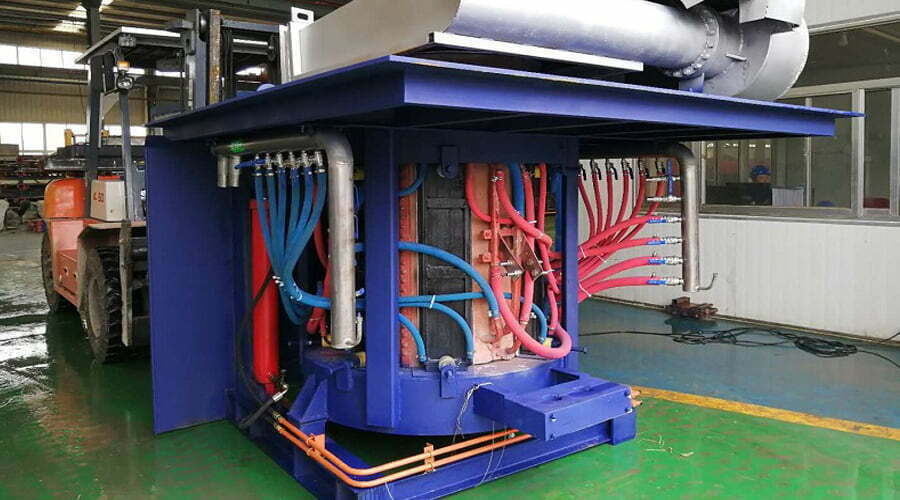

Induction Furnace For Steelmaking

In order to improve the production capacity of induction furnace for steelmaking, Hani Metallurgy makes reasonable designs in terms of hardware…..

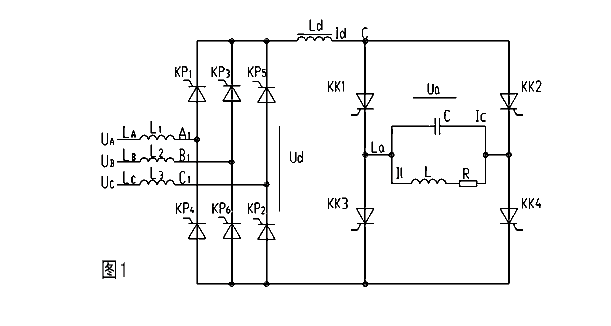

Induction Furnace Circuit and Principle

In the induction furnace, the induction furnace circuit is very similar to a transformer. The induction electrothermal effect is used to complete the metal smelting process. The power supply is generally divided into three types: high frequency (above 10 kHz), intermediate frequency (50 Hz ~ 10 kHz), and power frequency (50 or 60 Hz).

Induction Furnace & Vertical Continuous Casting Machine

Induction furnace + vertical continuous casting machine, an indispensable melting furnace and continuous casting equipment during smelting.

Precautions for Induction Coil of Foundry Melting Furnace

The core of the induction melting furnace is the induction coil. The effect and price of cold extruded copper pipe and cast copper pipe are very different. T2 cold extruded copper pipe with a rectangular section shall be used. The surface insulation treatment of copper pipe shall be treated with TSC-L ultra high-temperature insulation paint […]

How to Improve the Temperature Resistance of Induction Melting Furnace Lining?

Furnace lining refers to the furnace wall of induction melting furnaces or other furnaces used to refine metal. It is an important part of the working process of induction furnaces. The quality of furnace lining can directly affect the working efficiency of the electric induction furnaces. As high-temperature smelting equipment, the temperature resistance of the furnace lining must be the main standard to judge the furnace lining. So how can we improve its temperature resistance?

IF Non-Ferrous Refractories Requirement

This article is about some characteristics and the non-ferrous refractories requirement of induction furnace, colored refractory materials.

Refractory Materials Requirements of Induction Furnace

Refractory materials of induction furnaces, that is, materials with a general refractoriness higher than 1580 °C, are mainly used in induction furnaces.

Power-saving Method of Electric Induction Furnaces

Brief introduction of the power-saving method of Induction furnace

After decades of training, Hani Metallurgy has continuously developed and improved its products and kept improving, and summarizing a set of applicable power-saving methods for induction furnaces.

How to Maintain the Lining of Electric Induction Furnace?

The induction furnace needs to be lined when in use. Generally, nearly 400 furnaces can be used if the furnace lining is good. If it is not good, it may be used for dozens of furnaces, and the furnace lining may be broken.

Medium Frequency Induction Furnace Use Scope

The article is mainly about the application and characteristics of medium frequency induction furnace in metal smelting industry.