Induction Furnace Rolling Mill

Induction Furnace Rolling Mill for Rebar continuous casting and rolling production line. 4 sets of 5t induction furnaces are used to melt raw material scrap…

Induction Furnace Raw Material

Induction furnace steelmaking is put induction furnace raw material like scrap steel waiting to be melted in the furnace. When the induction coil is energized…

Induction Furnace Refractory Lining

Introduction of induction furnace refractory lining: it can be used in aluminum smelting, cast steel, and copper smelting.

This product is a refractory material for quartz coreless induction furnaces, and the material is acidic.

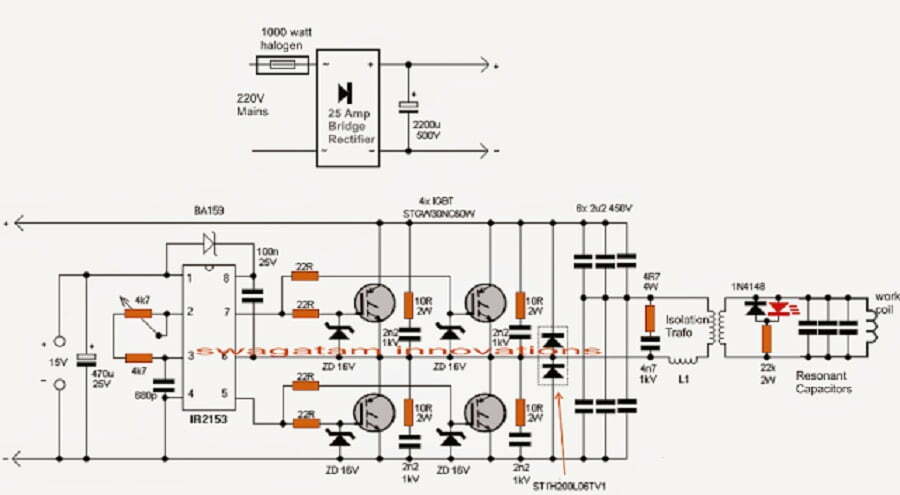

Induction Furnace Electrical Diagram

The working principle of the induction furnace electrical diagram is as follows: a three-phase bridge full-control rectifier circuit is used to rectify the alternating current into direct current, and after being smoothed by a reactor, it becomes a direct current power supply, and then through a single-phase inverter bridge, the direct current is inverted into a certain Single-phase intermediate frequency current with frequency (generally 1000 to 8000Hz).

Induction Furnace Electrotherm

Medium frequency induction furnace electrotherm is a new generation of metal heating equipment.Induction furnace electrotherm is an industrial furnace that uses the principle of electromagnetic induction to melt metal.

Induction Furnace Formula

The reasonable induction furnace formula for the furnace charge can avoid delaying the smelting time due to the adjustment of the composition, prevent the molten steel from being scrapped due to unqualified composition, and increase material consumption and power consumption.

Induction Furnace Power Usage

The 5 major Factors of Induction Furnace Power Usage Induction Furnace Intermediate Frequency Power Supply. The power density configuration…

Induction Furnace Efficiency Calculation

The induction furnace efficiency calculation needs to calculate the approximate power of the heating electric furnace according to the heating material, heating temperature, heating time, and process requirements.

Induction Furnace Cooling System

When designing the cooling system and pipeline of the induction furnace, we should pay attention to the following aspects: 1) Use copper pipes as much as possible for piping materials to prevent rust from entering parts.

Induction Melting Furnace Foundry

Induction melting furnace foundry (intermediate frequency electric furnace equipment) is used for melting ferrous or non-ferrous metals and alloy materials such as steel, copper, aluminum, zinc, nickel, gold and silver.