Description

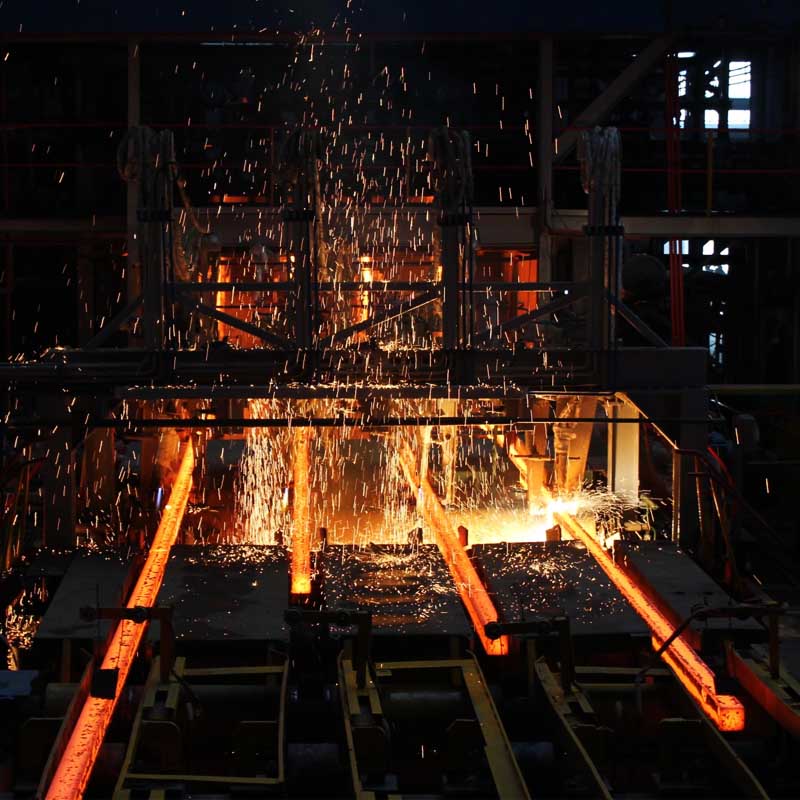

R9 Four-strands Continuous Caster

Description of R9 four-strands continuous caster:

1. Large turntable with weighing device and accident drive, variable frequency speed regulation

2. Tundish truck is driven by an AC variable frequency motor with fine-tuning transverse movement mechanism, which is convenient for protecting the casting and centering operation of the water nozzle.

3. Short arm four-link vibration, stable vibration, high frequency, small amplitude

4. Pull straightener adopts a five-roll pull withdraw straightener and continuous straightening technology to reduce slab deformation rate.

5. and effectively prevent straightening cracks.

6. A centralized chain drive is used for post-cutting, transport, and billet-discharging rollers

7. The billet discharging system is composed of the high pusher and rail cold bed.

8. The electrical automatic control system, with high equipment level, can realize automatic water distribution, automatic ruler cutting, and on-site picture display.

Parameter

Technical parameters of R9 four-strands continuous caster

Number | Item | Parameter |

Product Name | R9, Four-strand Continuous Caster | |

1 | Average tapping capacity of the converter | 35 |

2 | Casting steel grade | carbon steel |

3 | Billet Diameter | 150×150, Φ 200 (Reserved) |

4 | Caster strands Number/ | four-strands |

5 | Casting Radius | full arc / R9m |

6 | speed m/min operation/***large | 150×150 2.1/3.2 150 × 150 2.1/3.2 Φ200 1.5/1.8 Φ 200 1.5/1.8 |

7 | strands Spacing | 1400mm |

8 | production capacity | 80t-120t per hour |

9 | cast steel grade | alloy steel |

10 | cut-to-length | from 6m to 12m |

11 | ladle support | turret |

12 | tundish capacity | max.20t |

13 | tundish support | traveling car |

14 | Oscillation | non-sine |

15 | Straightening | continuous straightening |

16 | dummy bar | rigid dummy bar |

17 | cut machine | flame cutting machine |

18 | billet discharge | step-by-step cooling bed |

19 | annual output | more than 70,000 TPY |

Customized R9 Four-strands Continuous Caster

We can design and manufacture the R9 four-strands continuous caster according to the user’s steelmaking capacity, billet size, steel grade, and user site conditions. It can also be matched for manufacturers who already have continuous casting equipment.

Custom Range

Arc radius of casting machine: R2.5-10m

Billet species: square billet, round billet, slab, special-shaped billet

Continuous casting billet material: low carbon steel, low carbon alloy steel

Design production capacity: first-class 100,000 tons, second-class 200,000 tons, third-class 300,000 tons

Service

We can provide foundation layout and layout drawings

We will send engineers to your factory to install and debug machines and provide reliable after-sales service.

Competitive price and excellent quality

Our machines are easy to operate and maintain

Less investment

Stable performance

Products can be customized according to different need

Production capacity can be adjusted according to customer requirements

Low energy consumption

Reviews

There are no reviews yet.